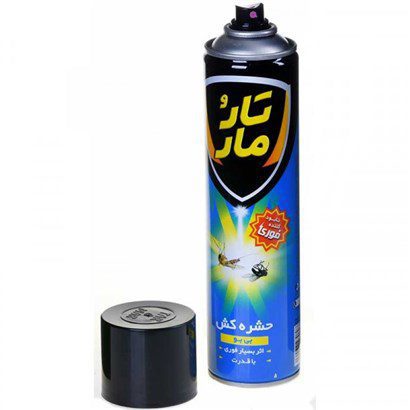

The use of spray cans for packaging insecticides and pesticides dates back to the history of spray production. The packaging type of spray cans, such as insecticide spray cans, has gained more attention due to its advantages compared to other packaging methods. Ease of use and the lightweight nature of spray cans are among these advantages.

In insecticide spray cans, the active substance, which is in a gaseous form, is compressed under high pressure and injected into the can as a liquid. When used, by pressing the spray valve (cap), the pressure inside the metal spray can decreases due to the pressure difference, and the liquid inside it is released as a gas.

Packaging insecticides in the form of spray cans has numerous benefits for consumers. These include ease of use when dealing with pests, high coverage radius, immediate effectiveness, and the fact that aerosol insecticides remain in the air and are considered the most effective method against flying insects.

In general, spray cans for insecticides are usually made of tinplate. Tinplate spray cans are a cost-effective choice for insecticides.

The process of producing tinplate spray cans includes manufacturing cans in various sizes and diameters, providing printing services on the cans, and filling the spray.

The packaging of Insecticide in the form of spray cans is usually done as follows:

- First, the printing stage on the metal is performed. The printing includes product name, expiration date, contact information, manufacturer, and safety warnings.

- The can is shaped into a cylinder, and its valve is mounted on the cylindrical body.

- Initially, water leakage is tested from the can to ensure there is no leakage.

- The valve is inserted.

- The Insecticide material is charged into the spray cans, and during this process, a certain amount of pressurized gas may be injected into the cans to prevent an increase in pressure inside the packaging.

- After charging the Insecticide material into the spray cans, the can lids are installed, and again, a strong pressure gas can be injected to seal them.

- Finally, the spray cans are packaged in boxes and prepared for market distribution.

Show reviews in all languages (3)

Reviews

There are no reviews yet.